Transformation of the Manufacturing Industry: Shaping the Change Together!

de-karb is an initiative under the Green Tech Innovation Program, launched by the Federal Ministry for Economic Affairs and Climate Action, to accelerate the energy transition in the industrial sector.

By partnering with industry leaders like Trumpf, Thyssen Krupp Materials Services, SES Ingenieure, Fraunhofer, DHBW, and AEC, TRACE-Electricity is driving the decarbonization of manufacturing.

Our tools and data provide the insights needed to understand electricity costs and CO₂ contributors, enabling companies to optimize their energy mix, lower operating costs, and reduce carbon emissions.

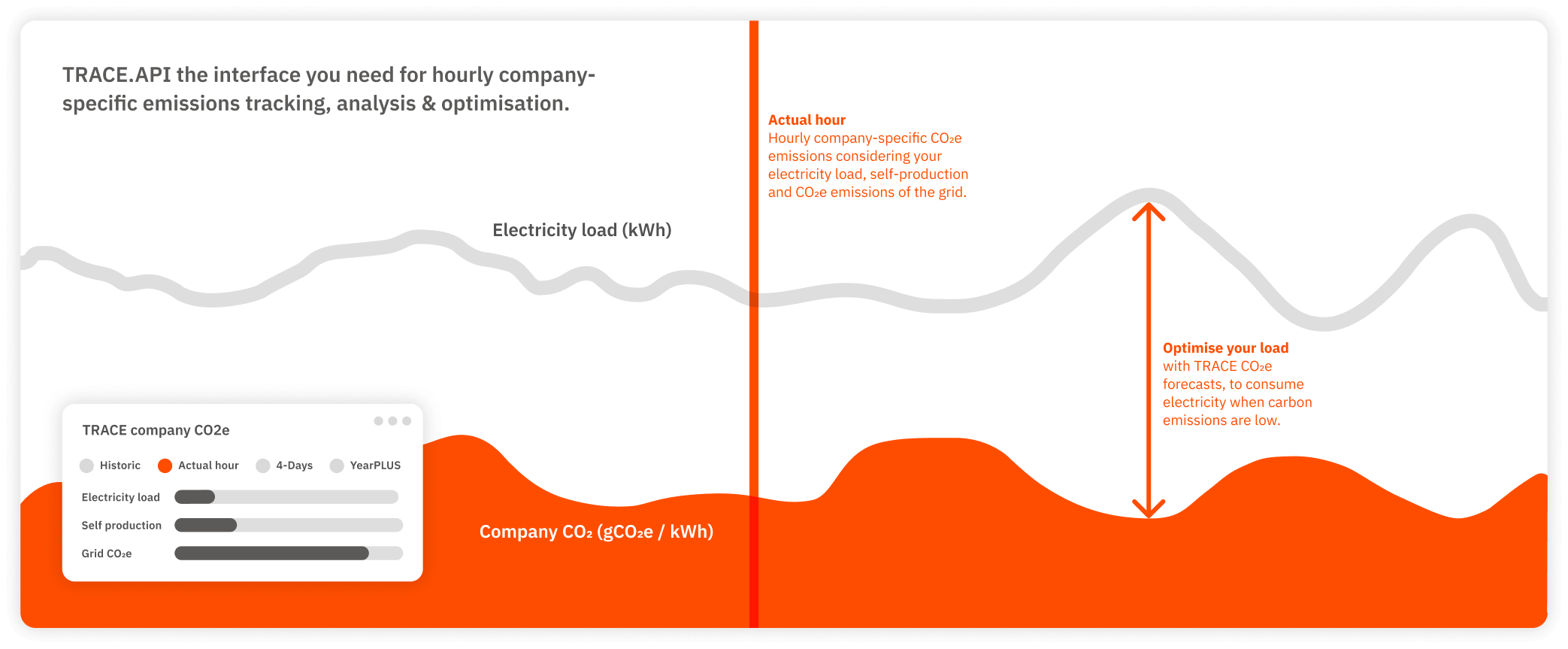

View and track CO₂ emission in real-time with TRACE hourly data

Gain hourly real-time insights into electricity cost and CO₂ emissions.

Integrate cost and emissions data into your operations and production processes.

Identify the CO₂ and cost patterns of your operations with the TRACE.App

Analyse your electricity load and self-production to understand electricity cost and CO₂ patterns of your operations.

Identify potentials to reduce CO₂ emissions and electricity costs.

Plan emissions and cost reduced operations

TRACE.App provides the easy-to-use interface to optimise your industrial operations and renewable self-production to reduce CO₂ emissions and save electricity costs for the German manufacturing industry.

Every business is different.

TRACE provides you with insights specific to your company, so you have what is needed to take action - hour by hour.

Load specific: Calculating CO₂ emissions TRACE considers your specific daily and seasonal load profile.

Self-production specific: TRACE CO₂ emissions consider available renewable self-production - PV and wind, both onsite and offsite via Power Purchase Agreements.

Keine Zeit verlieren!

Erfahren Sie, wie Unternehmen die TRACE.Plattform nutzen, um ihre Vertriebsdigitalisierung voranzutreiben.